RODIN CARS’ NEW 2500M2 FACILITY EXPANDS PRODUCTION AND DESIGN CAPACITY

MAY, 2021

NEW ZEALAND-BASED RODIN CARS ANNOUNCES SIGNIFICANT EXPANSION OF ITS DESIGN AND PRODUCTION CAPABILITY WITH 2500-SQUARE-METRE FACILITY

• Multi-million dollar facility includes capacity for in-house engine building.

• Facility is future-proofed for further expansion to over 7000-square metres.

• “You’re only as good as your worst supplier”, says David Dicker, founder and CEO of Rodin Cars. “So we try to do as much as we can from design to production. The decision to bring engine production in-house dictated a significant expansion of our facility.”

• The new facility was designed using the same computer programmes that Rodin Cars implements to design and develop its phenomenal Rodin FZED and Rodin FZERO track cars.

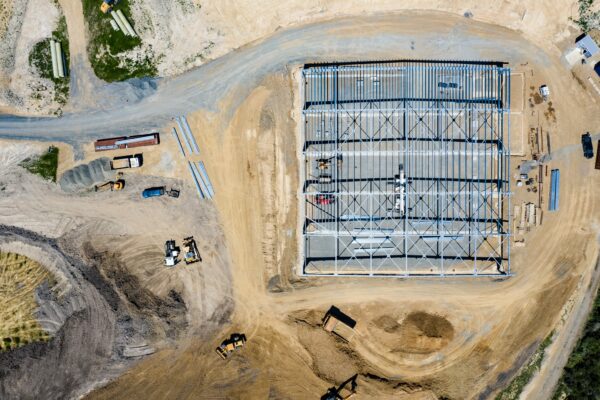

• Approximately 10,000 cubic metres of earth moved to level the site.

• In addition to the on-site design and manufacturing capabilities of Rodin Cars, the company’s 1400-acre HQ on the South Island of New Zealand features two configurable test circuits on which their supercars are developed.

Mt Lyford, New Zealand, 26h May 2021 – A year ago, as the world plunged into the unknown of COVID-19 lockdowns and restrictions, Rodin Cars confidently began drafting plans for an enormous expansion of its design and production facility. Using the same sophisticated computer design programmes that the company employs to design its Rodin FZED and Rodin FZERO track cars, the supercar manufacturer created a blueprint for a 2500-square-metre facility that will house all of the company’s works under one singlespan roof.

“Even though we already have around 1300 square metres of design and production facilities on site, we knew that we wanted to expand,” began David Dicker, founder and CEO of Rodin Cars. “We’re building a 50-metre by 50-metre factory adjacent to our current facility, so that’s 2500-square metres or 27,500 square feet. We’ll be able to do all engine manufacturing in there, we’re going to move all the 3D printers in there as well, which will free up space for the carbon fibre side of the business. And we’ll have a lot more room for design engineers as well.”

Indeed, 500 square metres of the new facility will be given over to the design offices, which will also benefit from stunning views of Mt Lyford through the 3.2m x 4.0m windows.

Rodin Cars conducted a geotechnical assessment of the site in June 2020, with earthworks beginning in October. Approximately 10,000 cubic metres of earth was removed to prepare the site for the enormous concrete slab, with the first pour for the foundations taking place on November 1. Just a month later, the erection of the steel framework began, and the build has progressed rapidly since, with the first prefabricated concrete walls lifted into place in mid-January this year. Each concrete wall section weighs approximately 20 tonnes.

By mid-March, the concrete floor, which features high-efficiency underfloor heating, was being poured, and the service installations began in April. The concrete floor is 200mm thick, but features numerous 600mmthick concrete isolator pads onto which heavy and highly-sensitive machinery will be bolted – including the state-of-the-art 3D Systems DMP Factory 500 printer that will be used to print the gearbox and exhaust system of the upcoming Rodin FZERO.

Once fitted out, the new building will house Rodin Cars’ engine production facility (including casting, 3D printing, machining, and assembly), engine test lab, and heated paint booth with downdraught extraction.

In addition to the increased space for design and manufacturing, the scale of the new factory allows delivery trucks to access the facility to unload inside the building or under the canopy at the entrance.

The estimated cost of the main construction is $6 million, though the final figure once complete will likely exceed $10 million, including internal fitout and machinery.

Watch more on the amazing new factory at Rodin Cars: HERE

About Rodin

Technical proficiency, engineering excellence and one of the largest and most diverse collections of the machinery and 3D printers in the Southern Hemisphere, are the foundations on which Rodin Cars’ is built. The automotive manufacturer has the capability to design and print many components of their bespoke supercars in-house – allowing the achievement and scrutiny of perfection to be more readily at hand.

Having the best team of engineers is fundamental to the achievement of everything that the FZED and FZERO were meant to be. The brightest up-and-coming thinkers and most adept craftspeople in the world of engineering have been sourced to achieve this goal. Partnering with the local university to support the engineering faculty is part of the Rodin Cars mission to promote and inspire the next generation of engineers.

When it comes to the Rodin cars – our engineers ensure there really is nothing like it.